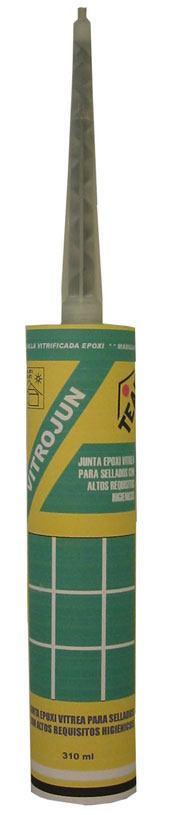

GLAZED JOINT WITH HIGH CHEMICAL AND MECHANICAL RESISTANCE WITH STABLE AND INTENSE COLOURS.

Glazzed putty based on epoxi resins based on water. VITROJUN is special for sealing with sanitary requirements in kitchens, toiletsm baths in hospitals, etc. The mixing of components is done during the process of extrusion.

It is suitable for grouting on floors or walls, domestic use, industrial, commercial and very suitable for using in hospital because of its ease of cleaning and no porosity. Suitable for areas exposed to chemical substances, environments with intensive transit, pools of new construction, grouting for refurbishmente on existing pools, areas exposed to abrup changes of temperature or freezes, etc. It sticks on surfaces covered with Gel Coat.

¡Compártelo o guárdalo!

According with dimensions of joint and tile.

One year in their original packages tightly closed and stored in cool and dry place.

2015-2017 SHIAC (ITC-20151250): DESARROLLO DE TECNOLOGÍAS DE HIGIENIZACIÓN PARA LA REDUCCIÓN DE RIESGOS BIOLÓGICOS EN ACUICULTURA

El proyecto SHIAC tiene como objetivo principal la investigación y desarrollo de una estrategia integral que permita reducir el riesgo biológico en acuicultura, integrando diferentes medidas tanto de tipo activo como pasivo para la prevención de patologías con una gran incidencia económica en el sector, y aportando soluciones más sostenibles ambientalmente a las actualmente empleadas en acuicultura.

Grupo Tres Mares S.A actúa como socio representante del consorcio empresarial que ejecuta este proyecto el cual ha sido aprobado y subvencionado por CDTI en el marco de la convocatoria FEDER INNTERCONECTA 2015.